Lamelmac pl-706

Technical Details

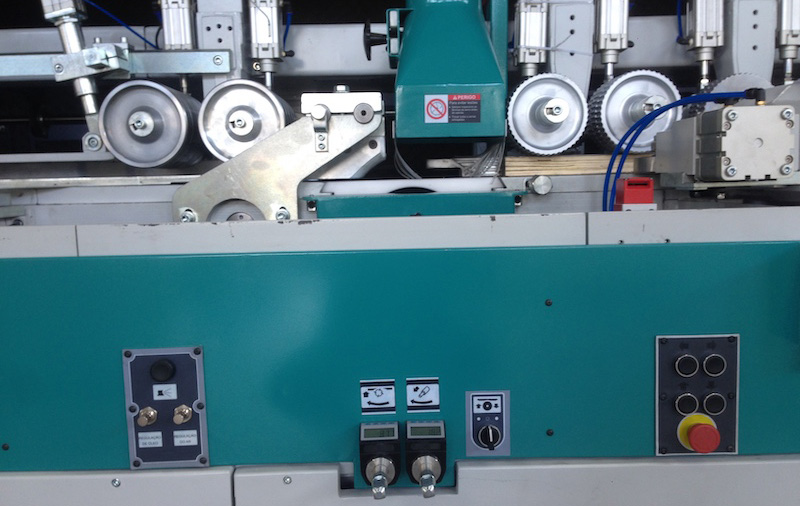

Pushbuttons for saw lubrication, with digital counters for a better position for saw cutting. With centralized lubrication and autoamtica of the machine.

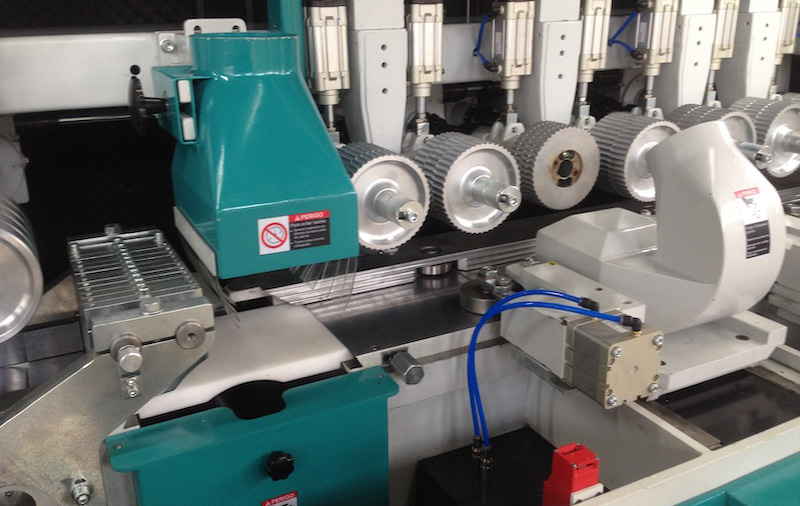

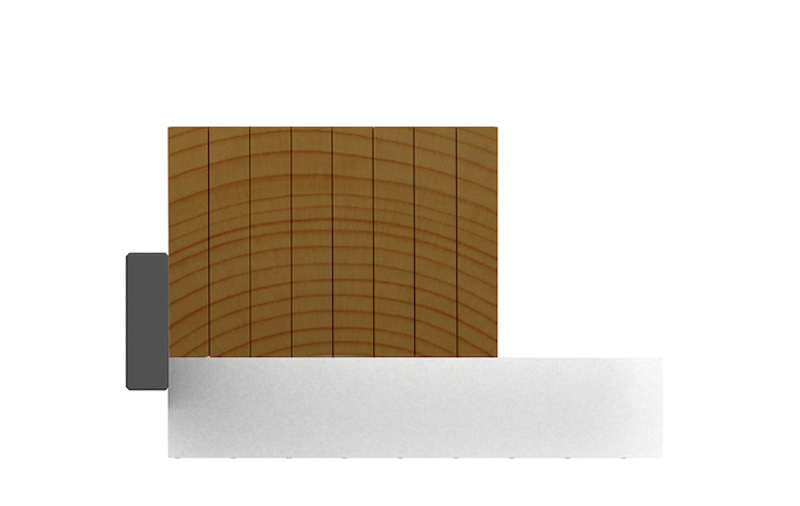

High thrust input presses for better compression in the wood and with a linear guide system to improve their position accompanied by the tupi in its automatic positioning.

Saw cutting system before the garlopa allows to improve and reduce the waste of wood to make the lamellae.

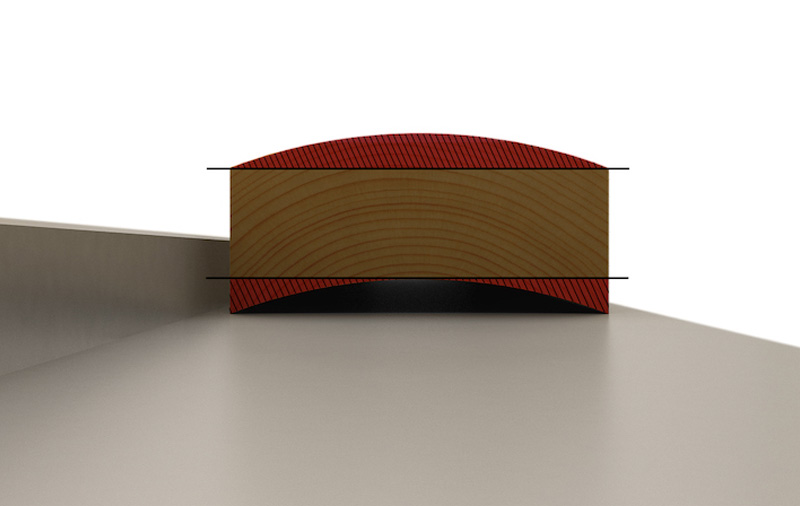

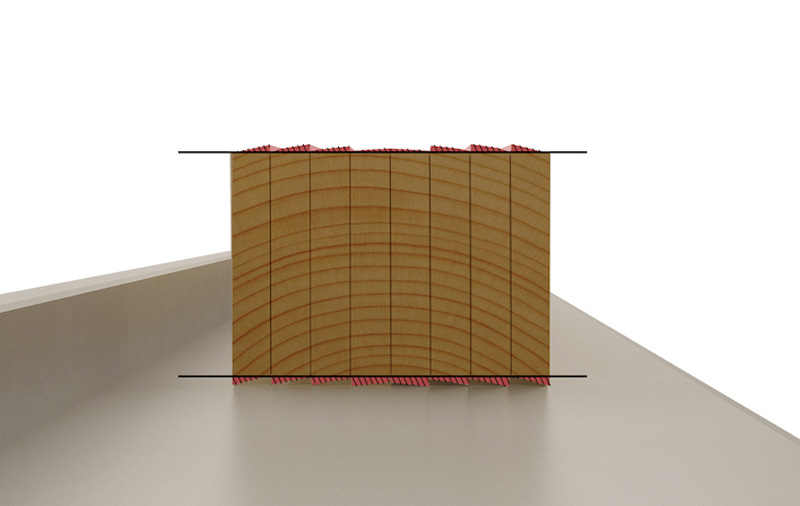

1 - Wood entering the machine; demarcated area is by way of representation what a garlopa or brush would remove in the wood.

2 - The wood being cut into lamellae before entering a garlopa or brush.

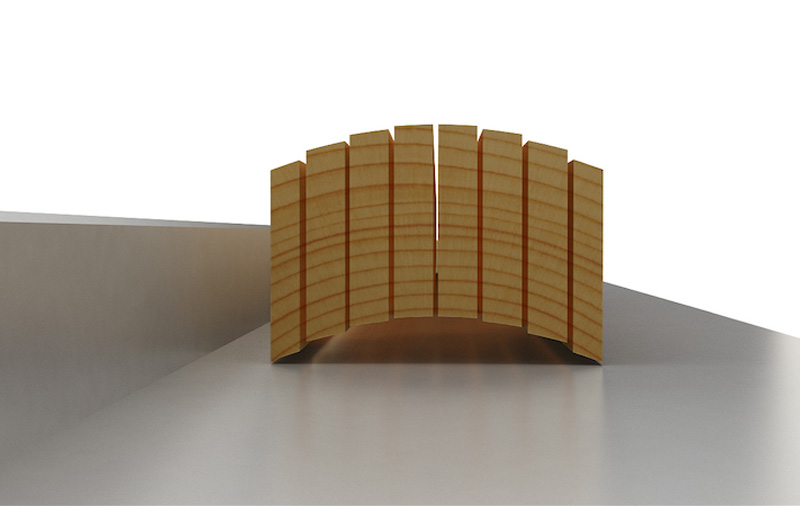

3 - Wood already cut into lamels fall and match on the table causing garlopa and brush to eliminate less material and make it possible to take advantage of more wood.

4 - Wood already processed by the machine has a better optimization of this since it previously passed through a saw before the entire brushing process.

Remote control panel, with different functions such as speed indicator, wood meters processed by the machine, touchscreen with different functions such as alert on machine functions and errors, lubrication and maintenance time settings, among others.

Last two axes against supports that allow to improve the finish in the wood.

Electrical cabinet independent of the machine that links the machine with its charger.

The motors have brakes that allow a better optimization of time since when the cabin is opened the axles brake quickly and allows a better set-up of the machine.

Axis Configuration

Technical Specifications

| Feed Speed |

|---|

| 10-60 m/min |

| Working Width |

| 20-230 mm |

| Working Height |

| 6-125 mm |

| Diameter of Axis |

| 50 mm |

| RPM of Axis |

| 6000 |

| Axial Movement of Axis |

| 40 mm |

| Radial Movement of Axis |

| 10 mm |

| Tractor roll train top / bottom to the entrance |

| Tractor rollers lower output |

| Feed Table Length |

| 1300/2000 mm |

| Soundproof Booth |

| Brush Presser |

| Neumáticos |

| Drag Roller Diameter |

| 160 mm |

| Circulo corte 1º inferior (sierra) |

| 250-300 mm |

| Circulo de corte 2º Inferior |

| 250-300 mm |

| 1st Top Circular Cut (Saw) |

| 150-200 mm |

| 3rd Bottom Cirucular Cut (Saw) |

| 150-200 mm |

| 2nd Top Circular Cut (Saw) |

| 150-200 mm |

Motores

| 1st Horizontal Bottom | |

|---|---|

| 75 hp | |

| 2nd Horizontal Bottom | |

| 20 hp | |

| 1st Horizontal Top | |

| 20 hp | |

| 3rd Horizontal Bottom | |

| 20 hp | |

| 2nd Horizontal Top | |

| 20 hp | |

| Drag System | |

| 30 hp | |

| Bridge Movement | |

| 4 hp | |

| Voltage | |

| 380 V | |

| Frequency | |

| 50 Hz | |

| Command Voltage | |

| 24 V |

Request Quotation

Bv. Berritela 7400

Córdoba, 5147

Argentina

Our working days are Monday to Friday and our hours are from 8:30 to 16:30.

Fill out the form to recieve a formal quotation.