Hector dl-7007

Technical Details

Three position selectors that allow the brake to be released for different applications, push buttons for automatic jointer.

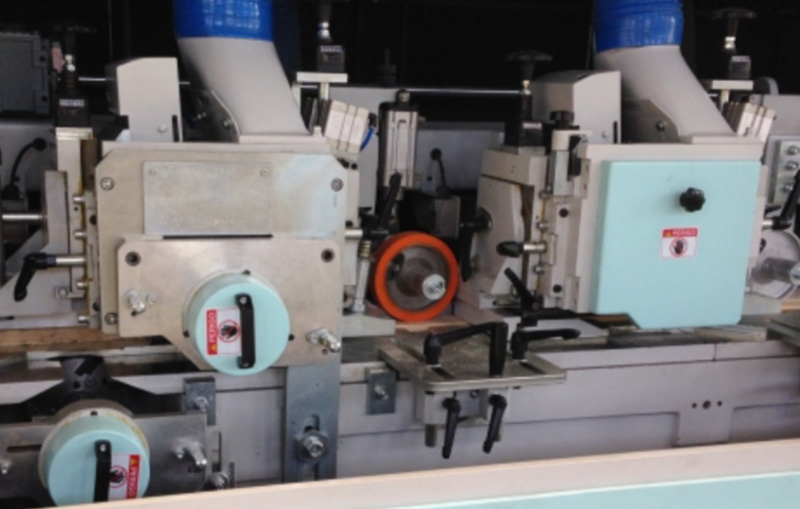

Hiraulically contra-supported ends ensure absolute rigidity in the total length of the work spindle, allowing large parts to be machined at high speed while maintaining the same quality throughout the piece. The axial adjustment is made without the need to remove pressure from the support.

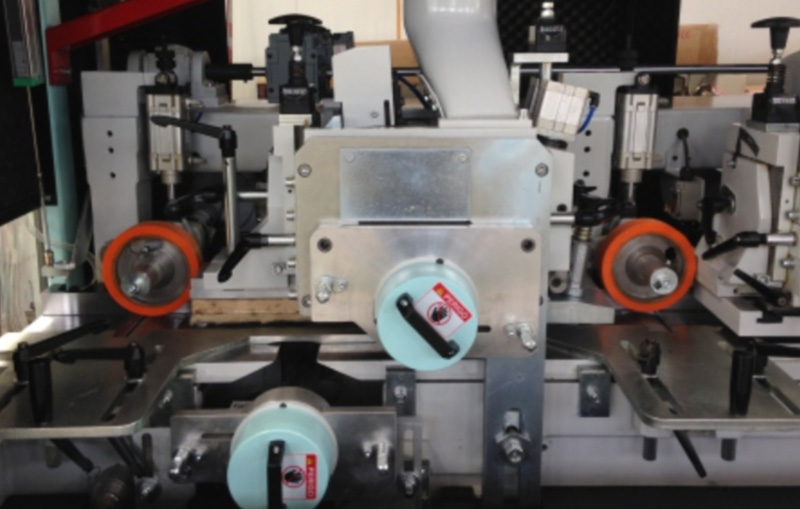

The tilting drag bridge greatly facilitates the machining of angled profiles, and with 100% effective traction in the feed, since the entire surface of the drag rolls make contact with the wood.

Dashboard, to control the machine remotely, with different functions, also has a digital display that allows a better arrangement of machine information.

Optional, chrome tables and guides for the work of abrasive materials, such as MDF, prolonging the useful life for many more years.

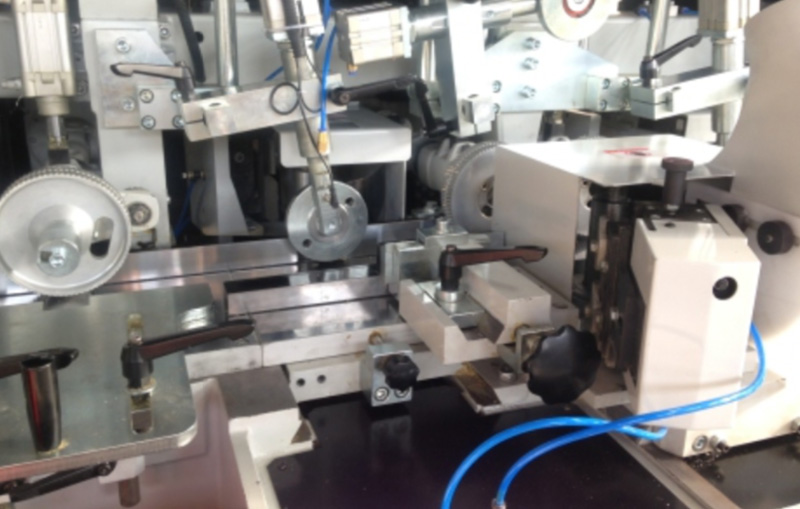

Rigid jointers of form with pneumatic drive of 0.017 mm of advance for each pass that ensures a long useful life of the tool. This mechanism that allows to obtain optimum surface qualities of high velocity termination.

Quick adjusting exit clamp for better tuning.

Strong input and output adjustment presses, with quick adjustment for better tuning.

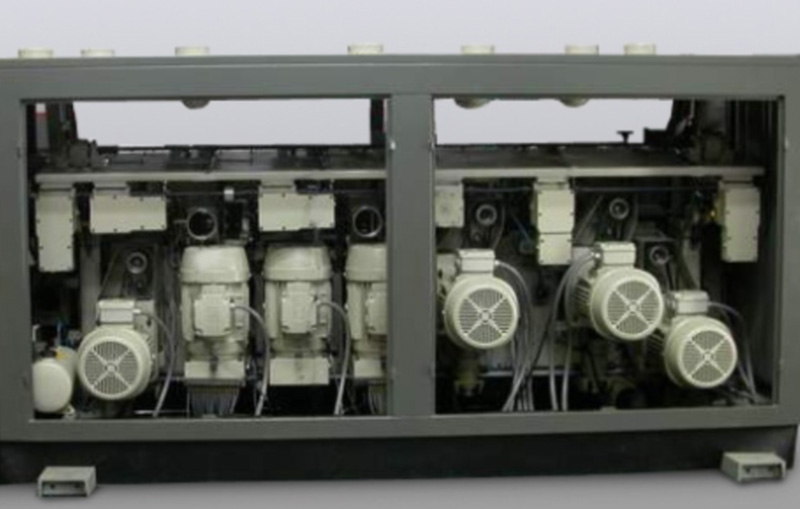

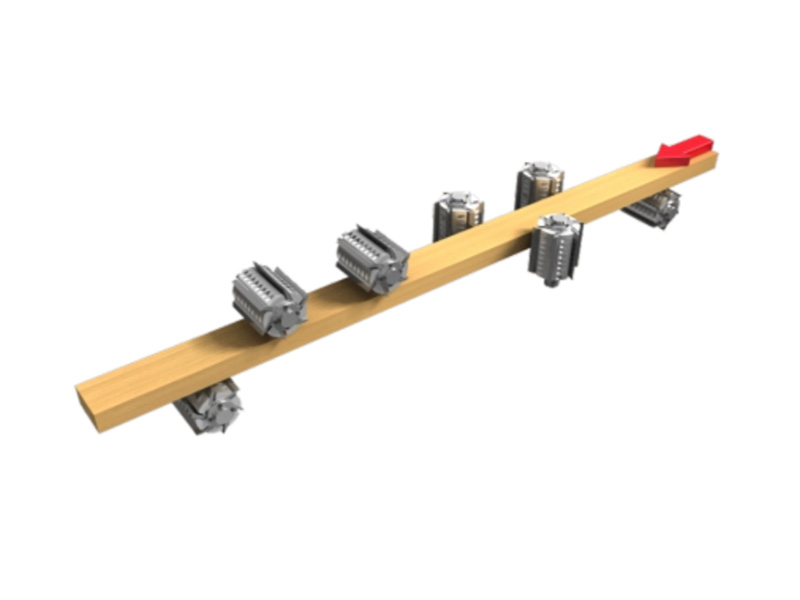

Gimbal feed system, with 4-input high-resistance gearboxes, gives the machine great drag safety. Individual motors for each spindle, supported by robust cast iron supports.

Pneumatic brakes for each axle allows a better application and utility when calibrating.

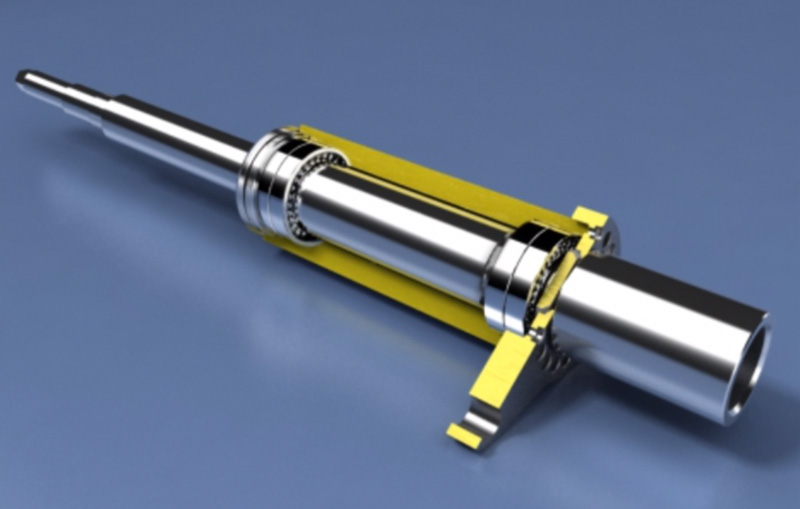

Cross section of the precision axes showing the configuration with paired angular contact bearings, without a doubt that this design allows a serene ride, to obtain quality at high forward speeds.

Quick adjustment for brush entry shoes, allows quick placement without the need to use a dial handle.

Axis Configuration

Hector dl-7007

Universal

Splitter

Technical Specifications

| Min-Max Width (Tool Diameter Ø140mm) |

|---|

| 20-230 mm |

| Min-Max Height (Tool Diameter Ø140mm) |

| 6-125 mm |

| Min-Max Number of Spindles |

| 4-10 |

| Spindle Speed |

| 6000 rpm |

| Min-Max Cutting Circle (Horizontal) (exc. 1st horiz. bottom Ø180mm) |

| 125-250 mm |

| Min-Max Cutting Circle (Vertical) |

| 125-250 mm |

| Spindle Diameter (Hardened) |

| 50 mm |

| Frequency Controlled Feed Speed |

| 9-120 m/min |

| Feed Rolls Diameter |

| 160 mm |

| Max Pneumatic Pressure in Drag Rolls |

| 6 bares |

| Rango de movimiento axial de ejes horizontales |

| 22 mm |

| Rango de movimiento axial para ejes verticales |

| 30 mm |

| Longitud de mesa de entrada |

| 966 mm |

| Pneumatic brakes on horizontal-vertical spindles | |

| Upper and lower motor drive rollers | |

| Changeable work tables | |

| Gimbal transmission | |

| Pneumatic Orbital Entry Presser | |

| Split pneumatic clamp adjustable to the hta. in horizontal spindles | |

| Presser input and output of horiz axes. fast orbital adjustment | |

| Automatic table lubrication | |

| Centralized grease | |

| Exchangeable tables | |

| Tables Adjustable to Tools of Vertical Spindles | |

| Soundproofing enclosure | |

| Hydraulic Support on Horizontal Axes | |

| Straight/Shape Jointer | |

| Hard Chrome on Tables and Guides | |

| Tilt Bridge |

Opcionales

| Max width 300mm |

| Repowering of motors on horizontal axes (up to 40 HP) |

| Roller feed extension |

| Multi Voltages |

| Working height 125 mm |

| Hydrocentral Tools |

| Tool Measuring device |

| Splitter |

| Universal |

Request Quotation

Bv. Berritela 7400

Córdoba, 5147

Argentina

Our working days are Monday to Friday and our hours are from 8:30 to 16:30.

Fill out the form to recieve a formal quotation.