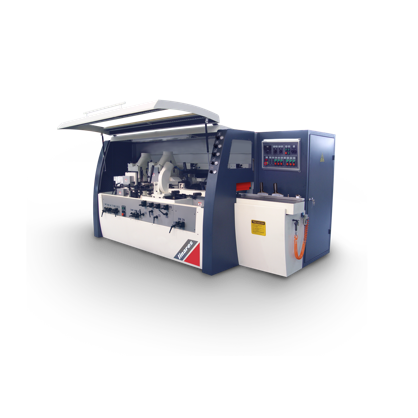

Technical Details

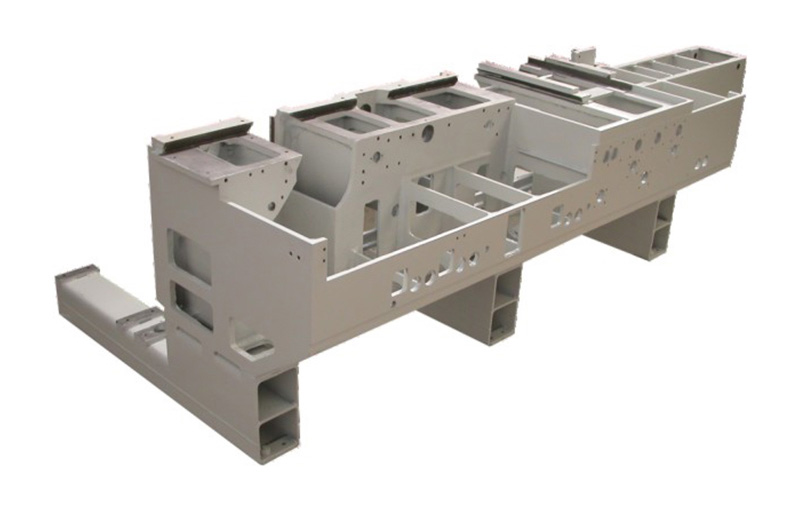

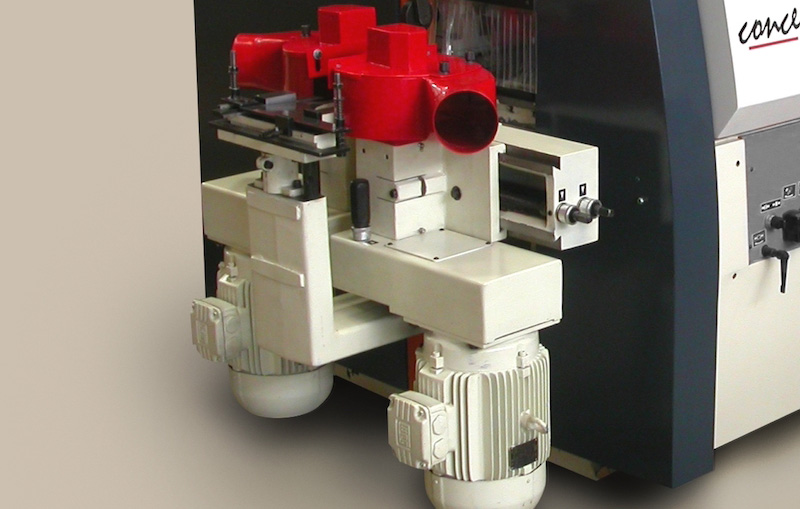

The cast body as a cast iron monoblock guarantees a unique stability when machining high-quality products at high feed rates.

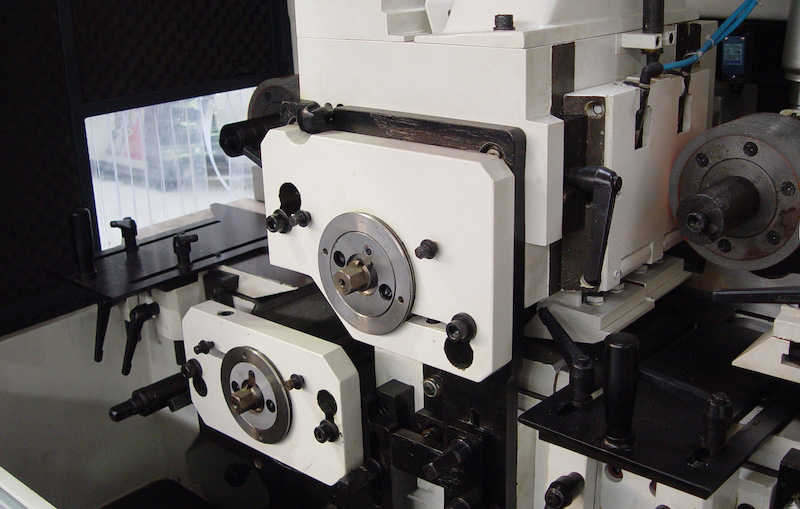

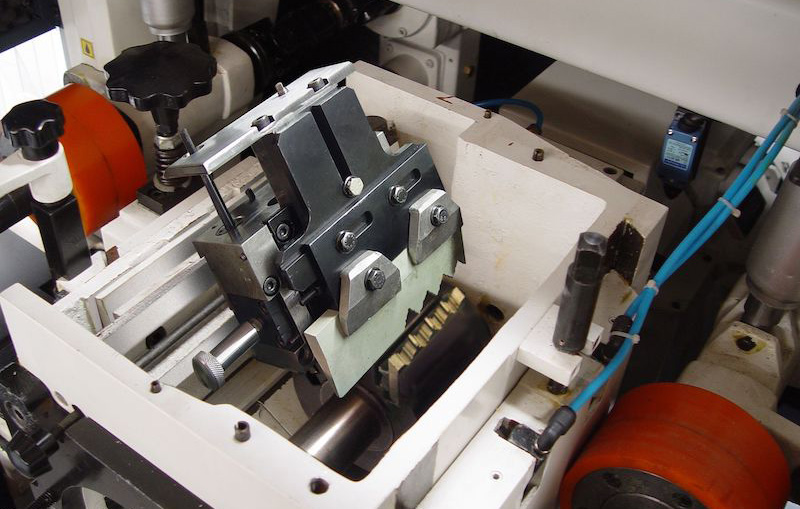

Pneumatic upper horizontal entry clamp with very easy adjustment, when it is necessary to adjust it to different cutting circles in short times.

Forward speed system controlled by electronic frequency inverter, indicated on the control panel by an electronic meter regulated by a potentiometer.

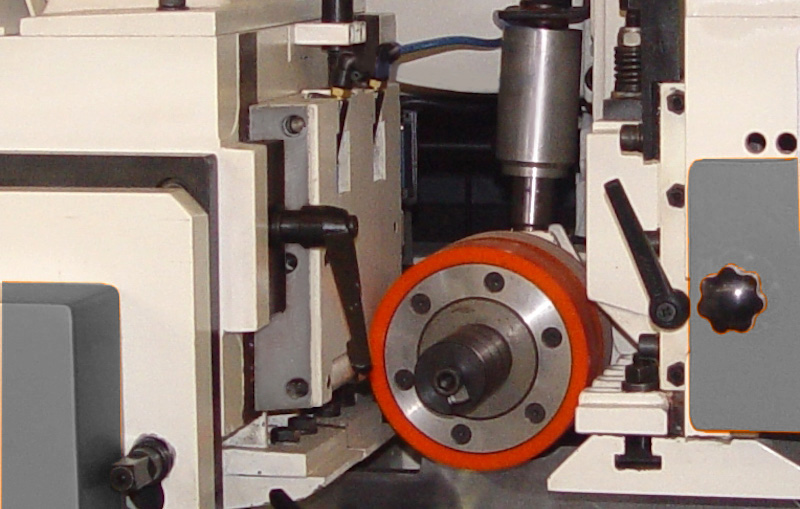

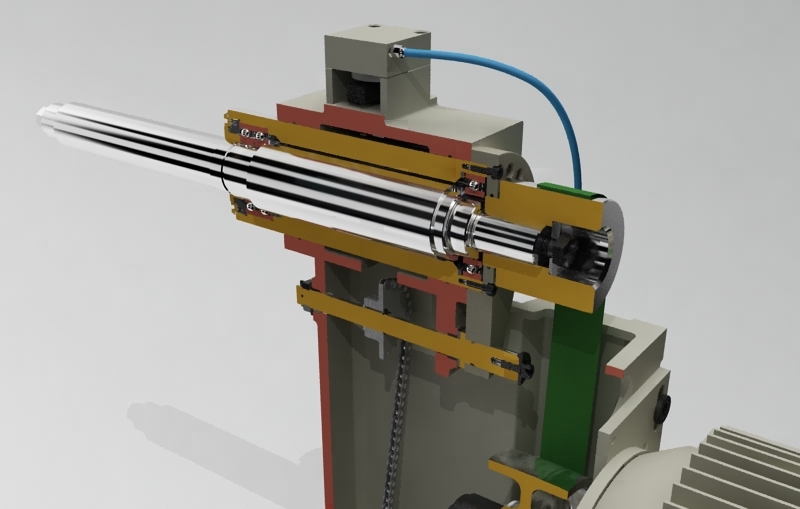

Precision axle design with double pair of angular contact paired bearings, which undoubtedly allows a serene ride, to obtain surface quality at high forward speeds.

Gimbal feed system, with high-strength gearboxes, gives the machine great drag safety. Individual motors for each spindle, supported by robust cast iron supports.

Hydraulically counter-supported ends ensure absolute rigidity, allowing mexanize wide pieces at high speed while maintaining excellent termination. The axial adjustment is performed without removing the hydraulic pressure.

Optional, chrome tables and guides for the work of abrasive materials, such as MDF, prolonging its utility for many more years.

Rigid straight and shaped jointers with 0.017 mm movement for each pass that ensures a long tool life. This mechanism allows to obtain optimum surface qualities of termination at high speeds.

Module of split saws at the exit very useful for opening wood, ex. Double machimbre and raw material optimization.

Exit rigors of great rigidity, allowing these deep cuts of wood with a great stability of the same.

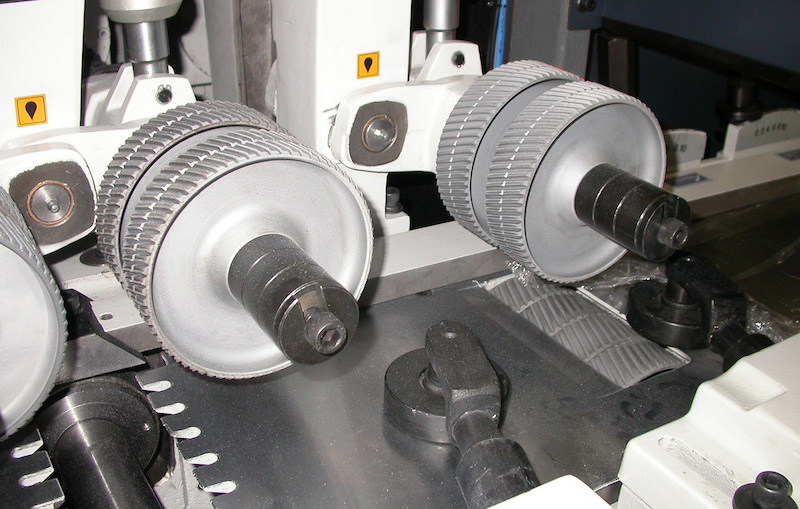

Robust system of continuous upper and lower traction, allows excellent drag from small parts to large beams.

Individual pneumatic locking of the axial movement of the horizontal axes that allows adjusting the axes from outside the machine with the cab closed, simply with the movement of a valve.

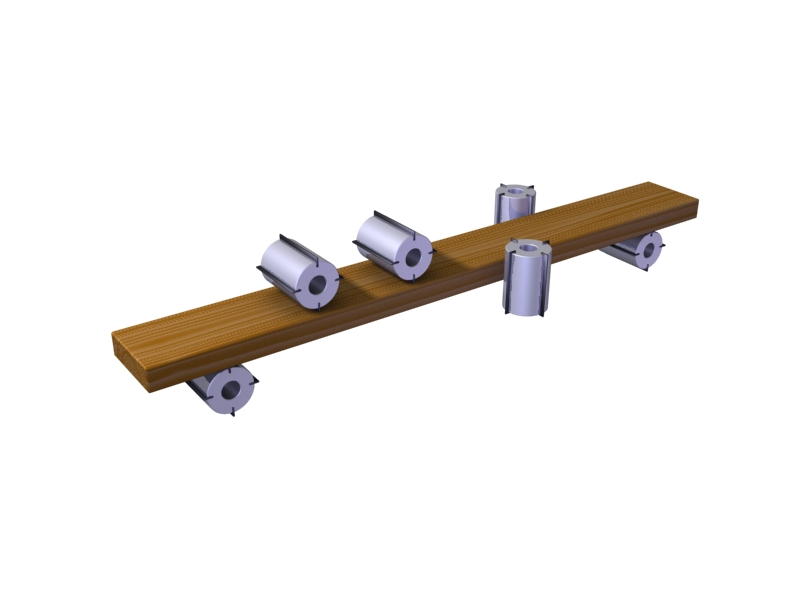

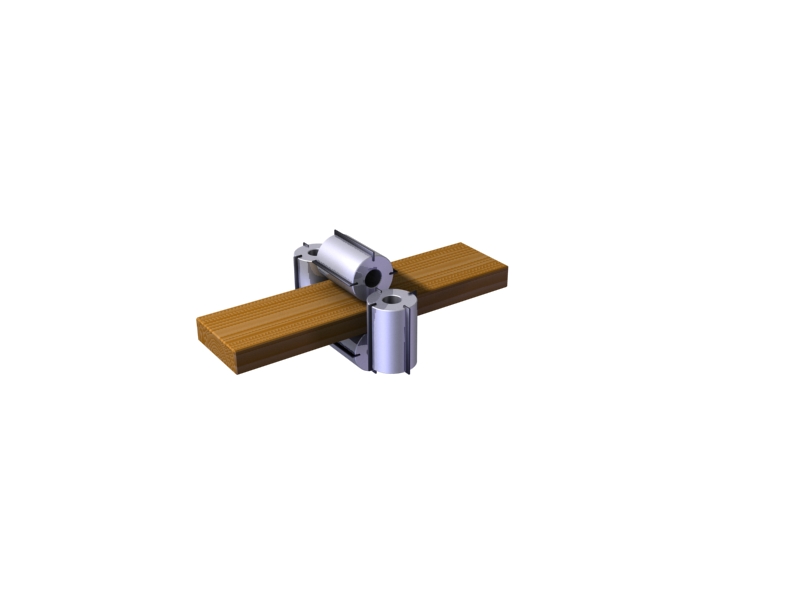

Axis Configuration

Concept dl-4006

Universal

Partidor

Technical Specifications

| Min-Max Width (Tool Diameter Ø140mm) |

|---|

| 20-230 mm |

| Min-Max Height (Tool Diameter Ø140mm) |

| 6-125 mm |

| Min-Max Number of Spindles |

| 5-10 |

| Spindle Speed |

| 6000 rpm |

| Min-Max Cutting Circle (Horizontal) (exc. 1st horiz. bottom Ø180mm) |

| 110-200 mm |

| Min-Max Cutting Circle (Vertical) |

| 110-200 mm |

| Spindle Diameter (Hardened) |

| 50 mm |

| Frequency Controlled Feed Speed |

| 10-100 mts/min |

| Adjustment Range for Infeed Bed Plate and Fence |

| 10 mm |

| Axial Movement for Horiz-Vertical Spindles |

| 22 mm |

| Feed Rolls Diameter |

| 140 mm |

| Max Pneumatic Pressure |

| 6 bar |

| Infeed Table Length |

| 2000 mm |

| Min. Stock Length |

| 228 mm |

| Upper and Lower Driven Feedrolls | |

| Bed Plates Exchangable and Adjustable to Tool | |

| Cardan Drive System | |

| Air Loaded Receding Chipbreaker in Front of Top Spindles | |

| Air Loaded Automatic Oil Pump | |

| Centralized Lubrication Points | |

| Pneumatic Clutch (Top Spindles + Feed Rolls) | |

| Remote Controls for Emergency Stop, Feed Jog and Feed Works | |

| Full Sound and Safety Enclosure |

Potencia de Motores

| 1st Bottom Horizontal | |

|---|---|

| 7.5-25 hp | |

| Left Vertical | |

| 7.5-12.5 hp | |

| Right Vertical | |

| 7.5-12.5 hp | |

| Horizontal Top | |

| 10-25 hp | |

| 2nd Horizontal Top | |

| 10-25 hp | |

| Second Horizontal Bottom | |

| 7.5-25 hp | |

| Universal | |

| 7.5-12.5 hp | |

| Elevation | |

| 2 hp | |

| Motor de arrastre | |

| 5.5-10 hp |

Optionals

| Hydraulic Support in Horiz Axes. (except 1st Horiz. Bottom) |

| Linear Jointer |

| Shape Jointer |

| Motor repowering |

| Hard chrome on tables and guides |

| Slotted tables |

| Roller feed extension |

| Shaft Diameter 40mm |

| Higher spindle rotation speed up to 8000 rpm |

| Long entry table (2000 mm) |

| Multi Voltages |

Request Quotation

Bv. Berritela 7400

Córdoba, 5147

Argentina

Our working days are Monday to Friday and our hours are from 8:30 to 16:30.

Fill out the form to recieve a formal quotation.